Oscillon Swiss Watches Crafted From Historic Tools

A watchmaking collective refurbishes vintage machines to create a modern watch

Additional reporting by David Graver

Authenticity plays a major role in the perception of Swiss watch brands. From the movement that makes it tic to the hand-finished elements that present the intricate craftsmanship, each brand celebrates its own distinct signature. Oscillon, a new company started by two young but established watchmakers—Cyrano Devanthey and Dominique Buser, who first spoke about making a watch back when they were in school together—take the heritage and legacy of Swiss watchmaking a step further.

This traditionally trained duo first sought out to find and then restore the types of watchmaking machines generations of watchmakers before them had used and perfected. They then set down a path to design and build a watch that represents their modern point of view but is entirely handcrafted using the tools of the past. Along with a small team of watchmakers, including two recent graduates—David Friedli and Jonas Plüss—and a little help from watchmaker friends, they’ve just released their debut watch, the stunning L’instant de Vérité (the Moment of Truth). Built and assembled by hand, the L’instant de Vérité features a proprietary manually wound mechanical movement. Working entirely by hand takes time, and limits production to ten watches a year.

To get a better understanding of Oscillon’s history we got an exclusive interview with founder Devanthey—who by day, along with partner Dominique Buser, work on research and development and CAD engineering for the impressive timepieces at Urwerk. Devanthey touches upon the sensations of a 20 year dream turned reality.

Who are you guys and why did you set up to create Oscillon?

We are some watchmaker friends who have been collecting traditional machines for about 20 years. Dominique remembers a discussion together with me at the time we were at the watchmaking school in Solothurn, Switzerland, where we talked about “you know once the apprenticeship finished we could build our own watch” this was back in 1990… The seed was planted… We also have two young, recent graduate watchmakers who work on the project. This is to keep the next generation in mind and make sure the craftsmanship and skills will not get lost.

With so many new tools available why would you want to find old machines, restore them, and work with them?

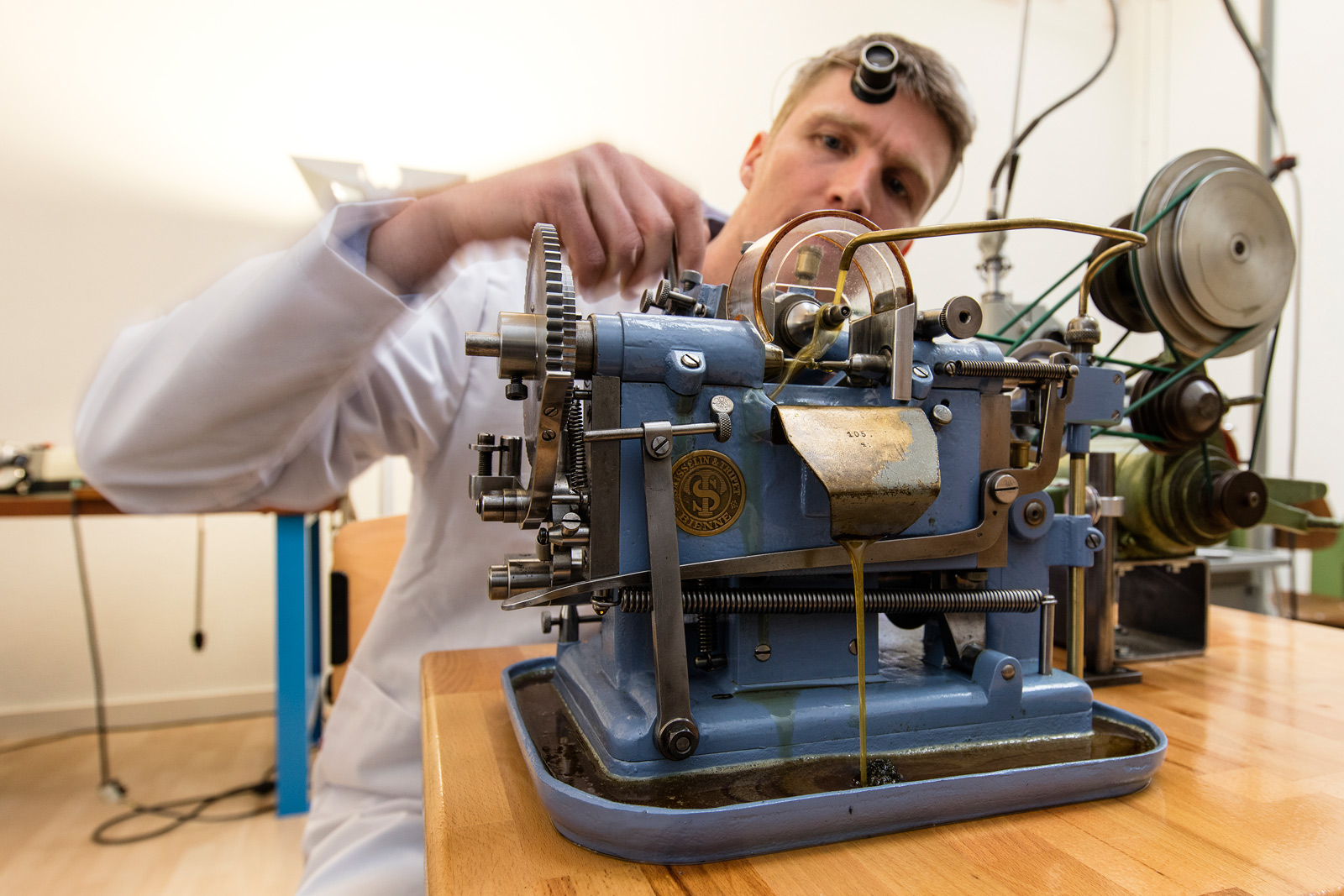

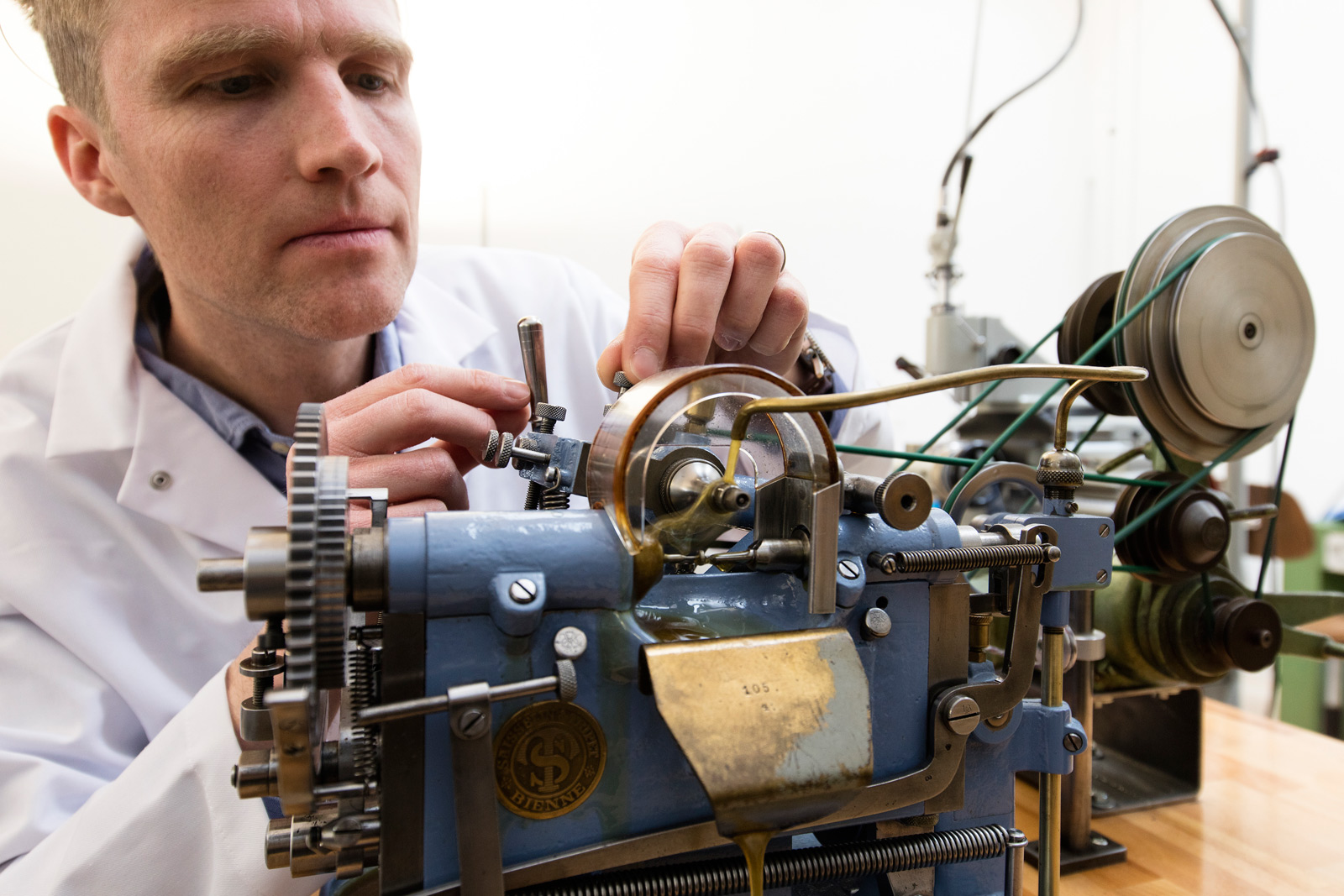

If you look 150 or 200 years back, the old masters in watchmaking created amazing watches without any CNC machines. We are fascinated by those watches and wondered if we could do the same today. We created our own policy for the manufacturing of each single component—from the main plate to the balance wheel until the last screw—all components are manufactured by hand on non-NC controlled machines.

What we like about those old machines, is that they become obsolete as soon as a new technique or procedure was invented. This means that the last machine before that point are always at the peak of their generation. Those are the machines we are looking for. Once you find the perfect machine for the job you have to get into it and find all the small adjustments which are necessary to get a perfect result. Sometimes you are lucky and can talk to an “old” man who was working on those machines, but most of the time you have to find out by yourself.

Are you using modern tools like CAD and then bringing them to life using the vintage machines?

Yes, the development and the plans are done in CAD but as soon as it is on the paper no computers are involved anymore in the manufacturing process.

What’s the design inspiration behind L’Instant de Vérité, your first watch?

As we produce everything by hand on traditional machines you can find a “mechanical” signature completed by the hand decoration and finish in our watch. The CNC machines can be fed with almost no limits in terms shape and design. This is not the case for manually operated machines…We are inspired by the old masters, but brought also actual decorations and engineering into our first model.

What significance does the name hold for you?

L’instant de Verité means “the moment of truth.” What began with a dream more than 20 years ago and now after more than five years of development and manufacturing—the moment of truth is when you hear the first tic tac. After all this time you get a tingling sensation in your stomach when the watch begins to live. We worked so long and hard for this moment (that) we named our first watch about this particular moment.

The design and detail of the face feels like a balance between modern and classic styling. Can you tell us about your preferences for the hands, the guilloché, and other finishes?

As we love our old machines we are also interested in all the old, sometimes forgotten, manufacturing techniques. We have a guilloché machine [Lienhard rose engine] which still needs restoration. We are still looking for a straight line guilloché machine—if you know someone.

The dial on the watch has been done on a brocading machine. Funny side story about this machine: it comes from Güdel/Lienhard, in Bienne, which is about 80km away from our office—but we found the machine on eBay in the US, bought it from the seller, a machine dealer, and the machines travelled in a big wooden box by ship to Europe and then by truck to Switzerland back in its home country. We made several designs for the dial and hands, the inspirations came beside others from Breguet, Patek Philippe, Audemars Piguet and vintage Omegas.

The L’instant de Verité by Oscillon is 40mm and currently available only in red gold and limited to ten production pieces a year. It features a power reserve complication and a seconds subdial. It retails for 162’800 Swiss francs, and is available exclusively at Türler, Uhren & Juwelen in Zurich. A platinum version is in the works.

Images courtesy of Oscillon